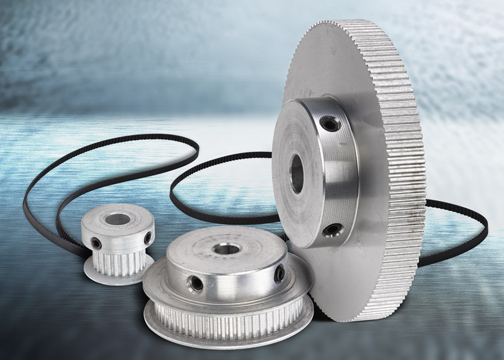

The type of application is critical in determining the best material for the pulley. The materials we use for our custom pulleys include aluminum, steel, plastic with an aluminum insert as well as plastic. With our computerized digital belt slitter, our belts are always made to meet exacting tolerances, and our pulleys a manufactured to the same high tolerances and performance expectations. Our team of experienced engineers can provide custom pulleys and belts of any material required. WHAT MATERIALS DO YOU USE FOR YOUR BELT PULLEYS? These may be stock equipment or, like our belts, they can be custom ordered to meet specific customer or industry standards and requirements.

Pulleys timing belts full#

In addition to timing belts and gears for any type of belt-driven equipment and products, we also offer a full range of belt pulleys. We work with specific industries, including robotics and computers, measurement equipment and instruments, and medical equipment manufacturers to create the precision motion control belt pulleys required for precise control of movement.

Pulleys timing belts iso#

Finally, it is important to consider whether the drive needs to be static-conductive to meet ISO 9563 (ATEX environments).OEMs requiring small to large volume orders of custom pulleys, timing belts, and gears can turn to JJC & Associations for stock items or those that are made to order to fit a particular piece of equipment. It is also important to know what ambient conditions are present and whether there are any space limitations (what is the maximum permissible diameter and width of the pulleys?).Ĭommon standards for toothed belt drives are DIN 7721 and ISO 5294. Several factors determine which toothed belt type is best suited to a particular drive, for example the application (what is being driven?), the power to be transferred, the desired speed (acceleration or deceleration) and the centre-to-centre distance between the pulleys. Of course, it is also possible to apply a particular surface treatment to the pulleys if the ambient conditions require it. Pulleys are also available in other materials such as plastic or stainless steel for specialised applications. Tooth belt pulleys are generally made of steel, cast iron (GG) or aluminium. Furthermore, we supply tooth belt pulleys to match customer specifications, and we can machine standard pulleys according to customer requests or drawings. Depending on the variant and number of teeth, the pulleys use either flanges and/or a hub as standard. Metric pulleys (T and AT) and those with imperial profiles (such as MXL, XL, L, H and XH) are mostly available directly from our stock. the Powergrip HTD, Powergrip GT and Poly Chain GT pulleys, all in standard or clamping bush variants. The most common tooth belt pulleys are stocked, e.g. The major advantages with using a clamping bush lie in the fact that the pulley and shaft do not have to be modified beforehand and that mounting and removal are very easy. They are supplied together with the appropriate socket head screws. The associated clamping bushes are available with bore holes in various sizes and with a key way in both metric and imperial dimensions. The clamping bush variant is equipped as standard with a conical bore and threaded holes for fastening the bush to the shaft.

The undrilled and pre-drilled variants must first be provided with a bore hole and possibly with a key way and a threaded hole. The clamping bush variant, also known as a taper or taperlock variant, is always used in combination with the associated clamping bush. As standard, tooth belt pulleys are available in undrilled, pre-drilled or clamping bush variants.

0 kommentar(er)

0 kommentar(er)